5G: Rethinking Established Solutions in Industry 4.0

Technological advancement often means not just embracing the new, but also questioning the established. Even in an industry world where WLAN infrastructures are firmly rooted, 5G shows us that there’s always room for improvement. It’s not just about introducing a “new technology,” but rethinking our current approaches: Are we truly as advanced as we think? The Future is Hyperconnectivity: 5G is at the heart of this revolution, aiming not just to connect people, but to deeply integrate the Internet of Things (IoT). This enables communications between sensors, devices, and machines that were previously unthinkable. With 5G, data transfers become faster, more reliable, and more efficient. A Paradigm Shift in Production: Visionary companies see 5G’s potential to fundamentally change production. Everything, except the floor, ceiling, and walls, will be flexible and mobile. This means more agile production that can quickly adapt to market changes. Securing Data Sovereignty: With 5G, companies have the opportunity to create specialized local networks tailored precisely to their needs. This means more control and security, ensuring transparency and protection from external threats. Easy 5G Integration: 5G accelerates the Internet of Things, promoting the transition to Industry 4.0. For this transition, machinery and installations need to become 5G-compatible. Fortunately, innovative control technologies make it simpler and more cost-efficient to adapt to this new standard. It’s easy to say, “We have WLAN, that’s enough for us.” But 5G offers so many benefits that it’s worth looking beyond the usual. It offers possibilities that current technologies simply cannot achieve. In conclusion, 5G is not just a new technology. It has the potential to completely change the way we produce, communicate, and interact. It’s not about if, but how we will adapt.

Digitalization in the D-A-CH Region: Visions and Reality

The advancing digitalization in the industry, especially in the D-A-CH region, was the focal point of the recently published “Zukunft Industrie 2023” study by Staufen AG. This comprehensive report, based on surveys of over 400 industrial companies, provides enlightening insights into the current state and future perspectives of digitalization. Dr. Michael Feldmeth of Staufen aptly summarizes the core of the challenge: “Many companies are still tentatively approaching the topic of digitalization with various projects that aren’t always coordinated with each other.” A significant point highlighted is the necessity for companies to think beyond mere digitalization and develop alternative business models. The study accurately portrays the status quo: These numbers compellingly demonstrate the need for further digitalization, especially in an age where technologies like smart factories and autonomous transport vehicles dominate Industry 4.0 discussions. Against this backdrop, MES systems, like the ones we offer, play a pivotal role in bridging the gap between vision and implementation. Our systems are key to harnessing the potentials of digitalization in practice. The Staufen study is a wake-up call for all industry stakeholders to actively engage with the challenges and opportunities of digitalization. For those interested in delving deeper into the topic, the study is available for free download. For those looking for an in-depth exploration of the study’s findings: It is available for free download.

Efficiency meets sustainability: packaging optimization as the way forward

The subject of packaging waste has received significant social and political focus in the last few years. Due to the growing awareness of sustainability, the issue of packaging waste has become one of the most important challenges for companies. In Germany, the scale of the problem is particularly dramatic: with 19 million tons of packaging used annually, the urgent need for an efficient and effective solution is becoming increasingly clear. This is not just an ecological and moral issue. Consumers themselves are becoming more and more concerned and alarmed by the flood of packaging waste. According to a study, 45% of consumers feel significantly disturbed by packaging waste and more than a quarter of respondents even stop buying products that, in their opinion, generate too much packaging waste. There is a clear consensus here: consumers see manufacturers as having a duty to reduce this waste. Almost half of all consumers, 45%, consider the producers of the goods to be primarily responsible for reducing packaging waste. However, it is not just a question of environmental protection. The economic demands and pressures are also increasing. From 2020 to 2022, the producer price index for wood packaging has almost doubled. Prices for other packaging materials, such as corrugated board or plastic, have also increased significantly. These rising costs for packaging materials are forcing manufacturers to put current operations and processes to the test and. It is obvious that changes need to be made to current practices and strategies and that comprehensive optimization of processes is necessary. Development of producer price index of packaging (DE) Packaging optimization: an effective way to shape the future In view of the growing challenges around packaging waste, packaging optimization from dmaic offers an efficient and effective solution. Our approach combines reduction of material consumption and efficient use of resources. By using modern technologies such as automation and 3D calculation, we maximize packaging utilization and minimize waste. The advantages are many: costs for packaging and logistics are reduced, unnecessary waste is avoided, and transport damage is reduced through careful planning and appropriate surface treatment. Thanks to our approach of looking at each packaging process individually, we are flexible and can adapt to changing part combinations and lot sizes. You can find more information about our diverse solutions here. Sources: Genesis online database – 61241-0003 Federal Environmental Agency Statista survey on disposal behavior

Ligna 2023

Today the Ligna in Hanover begins. Meanwhile, it has established itself as the world’s leading trade fair for the wood industry. The more than 90,000 expected visitors will be welcomed by 1,300 exhibitors who will be offering a wide range of tools, machinery and equipment for wood processing. According to the motto “change needs head, hand and heart”, another focus of this year’s trade fair is on the digital transformation of the wood industry. Thereby, the focus will be on the transformation of wood processing and woodworking and will discuss where the journey will lead to in the next years. Interesting panel discussions and lectures on digitalization along the value chain will round off the diverse offer. Even though we from dmaic are not directly on site as an exhibitor this year, we would like to highlight how important and exciting the trade fair is in our eyes. Our partners will be present with innovative solutions and impressive technologies. They represent the future of wood processing and technology at the show and it is definitely worth visiting their booths. If you are interested in getting more in-depth information, just take a look at the exhibitor directory at: https://www.ligna.de/de/suche/?category=ep. We are looking forward to an eventful week full of inspiration, knowledge and networking. We wish all visitors of the exhibition much success and a good exchange of knowledge. Take the chance to discover the latest trends and technologies in wood processing! For all those who cannot manage to be live on site, the fair offers live streams of different lectures and events. Find out more at: https://www.ligna.de/veranstaltung/ligna-stage/for/103935

April 22 – Earth Day

Since the first Earth Day celebration in 1970, this day has helped to raise environmental awareness around the world just a little bit. Today, we celebrate the beauty of our planet and take the time to once again focus on environmental issues. Nevertheless, today we would like to highlight some impressive progress and achievements in the European furniture industry, which is moving step by step towards greater sustainability and resource efficiency. → FSC-certified wood: The Forest Stewardship Council (FSC) has established a certification system for sustainable forest management. Around 190 million hectares of forest worldwide are already FSC-certified. In Europe, the use of FSC-certified wood in the furniture industry has grown steadily, reflecting increasing environmental awareness and the desire for responsible forestry. → Environmentally friendly materials: The industry is increasingly using recycled and environmentally friendly materials such as recycled plastic, bamboo or cork to reduce its ecological footprint. → Energy-saving production: In recent years, the furniture industry has been able to significantly reduce its energy consumption and thus reduce its environmental impact. → Circular economy: Upcycling and recycling initiatives help to minimize waste and extend the life of furniture. We are aware of the resource intensity of the furniture industry and are committed to helping conserve resources and be responsible stewards of our planet through efficient software solutions. Through our focus on innovation and sustainability, we support the reduction of environmental impact and work together with our partners towards a more sustainable furniture industry and thus a healthier planet.

Merry Christmas

The dmaic team wishes you and your loved ones a Merry Christmas and a Happy New Year!

From individual production to mass production

In the past, manufacturing companies could only offer predefined goods for sale. These products were mass-produced at a cost-efficient price. In recent years, the market has changed in that customers increasingly demand individualised goods. This is, for example, a wardrobe that is configured online to the millimetre, or a bicycle that is built uniquely in terms of appearance and equipment. However, buyers do not accept significant price increases for this. Attractive and cheap for customers, but often a big challenge for manufacturing companies. In order to produce a profitable product at an attractive price, so-called “batch size 1” production (also known as mass customisation) is used. Digital networking drives individual, efficient one-off production. With the help of digitalisation, automation and intelligent software solutions, such as the dmaic MES, processes and production are redesigned in such a way that maximum variable and efficient production processes are possible.

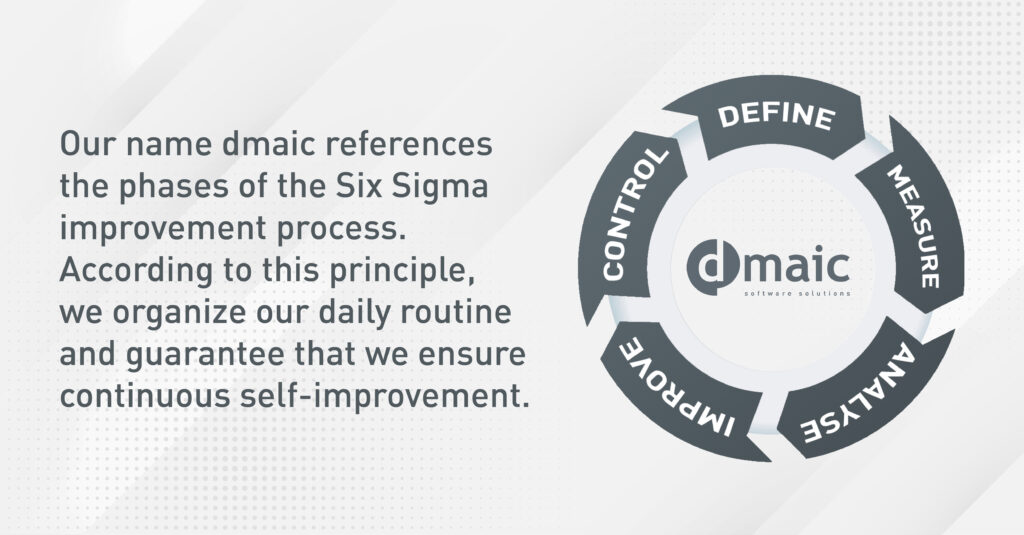

What does the company name dmaic stand for?

Have you ever wondered where our company name comes from? dmaic describes the process of the Six Sigma quality management approach. In everyday life, we design our projects and process flows according to this method and thus ensure that we achieve the best possible results and constantly improve.